Supply Chain Management

Order Instructions:

subject:

Managing Global Supply Chains

SAMPLE ANSWER

Supply Chain Management Strategy

Introduction

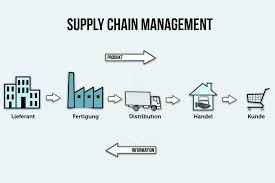

The concept of SCM (Supply Chain Management) has been in practice for centuries, holding a significant position in market business development. Companies involved with supply chain management usually emerge as the principal market developer and players. Supply chain management has integrated major business activities into a series of process that include the obtaining of raw materials, transportation, production and allocation and distribution (Lavastre, Gunasekaran and Spalanzani, 2014, p. 3382). How well and effective supply chain management has played in the development of companies can be traced to the development of the global market economy. It is through the effective management of supply chain that an integrated system of business operation has been attained globally. Companies can obtain products, distribute and supply all over the world. Hence, it can be observed that supply chain management is the backbone of business operation in helping companies achieves organizational objectives.

In the past several years the world has experienced an increasing economic volatility, as observed in the economic recession, customer demand, fuel and commodity pricing and the rapid movement of raw material (Sandberg & Abrahamsson, 2010, 57). This significantly continue to affect business objectives and daily operation. Companies must respond to conditions of reduced labor pool, stagflation, deflation, energy consumption and sustainability in attaining their organizational goals (Hamister, 2012, p.427). However, effective strategic supply chain management together with well-defined tools and plans will help alleviate the pressure that business organization is experiencing today and bring a change in market development globally.

Importance of Effective Supply Chain Management

Boost Customer Service

One of the primary objectives and core contribution of any business organization is to focus on how their clients are well attended and offering comfortable service to their clients (Milliken, 2012, 4). It is a business goal to attract most customers to the company as this triggers sales and general incomes for a company. This is only attained through a consistency working environment and service oriented toward clients. Supply chain management is the right tool in ensuring that companies achieve their objective of securing a stable and safe flow of customers throughout the year.

Customers are usually motivated by the effort a company put in providing service, care and attending to their needs and demands. Clearly, Supply chain management is an effective component of business performance. They ensure right product assortment, quality and quantity are delivered to the customer when they are needed and where. The supply logistic plays a major role in product allocation at different point of customers demand. SCM helps a company identify markets that are in high demand for their products and then respond promptly (Seuring & Gold, 2012, 555). Additionally, the system ensures that the clients receive quality service and streamline every business operation towards the satisfactory of the customers. A happy client is a good indicator of a prosperous business organization. Companies invest in their customers through boosting the efficiency of their supply chain management to satisfy the clients demand adequately and needs.

Inventory control and Visibility

The Enterprise Resource Planning is one of the pervasive tools for Supply Chain Management. ERP is responsible for controlling the flow of raw materials, from one point of production to the next throughout production. Its primary target is bringing a balance in the inventory control, inventory visibility and work order management, purchasing among many others. The Supply chain management through the ERP tool systematically coordinates the manufacturing operation, record keeping in the inventories efficiency (Kanungo, 2012, p. 2-3). It helps an organization to keep their complex facilities running smoothly, with any organization that has a well-defined inventory system. SCM is responsible for maintaining an efficient system, which in return bring low inventory cost and offers consistency in timely availability of products and services. This attracts more customer, investment and increases business operation and profits. Thus, SCM is considered an important ally of inventory management in improving productivity in attaining organization objectives.

Inventories determine the value of a company and are regarded as a valuable asset to any organization. Every business must establish a standard inventory turnaround that is equally optimum for the management and operation of the firm. The inventory turnaround dictates the company prosperity, and this is attained through having a well established strategic supply chain management system. In this case, Enterprise resource planning is responsible for the management, storage, and interpretation of the inventory and product in a company (Groznik, & Trkman, 2012, p.1101). It plays a significant role in the integrated view of business processes and activity. SCM through this tool is able to identify and track business activities, resources and raw material allocation, and the general production capacity of an organization. Through adopting a well-structured Supply Chain Management system, a company is capable of facilitating information flow and management connection both internal and external.

Capital Efficiency and Reduced Time-To-Market

The primary objective of business is to subsidize production cost and maximizes the output. This is significantly attained through the help of Supply Chain Management. Most companies that invest in supply chain management concentrate on demand forecasting, correct order management, and market allocation. This assists the company in avoiding waste and risk associated with distribution and supply of products as well as production. Supply chain management assists in identifying the right place to invest and the process through which the company can require resources and distribute their product without experiencing massive losses (Richey, et al., 2011, p. 365).

Demand prediction in SCM is effective in assisting a company maintains upfront in a competitive environment. Capital and cost of operation are equally controlled when the company forecast demand and provide a correct order management. Supply Chain Management responsively address customers request based on time management, product mix, flexibility, and quality (Arlbjørn, Freytag & de Haas, 2011, 277). This makes a company stays independent in a competitive market and reduce the cost of operation and management. The power of capital efficient and time management as expressed in SCM is substantial in the development of a company towards goal orientation. Every company with a well-structured supply chain system maintains a low cost of operation through saving time and avoiding product waste.

Improve Marketing and Sales Competitiveness

The main aim of business is to make a profit through marketing and sales. Every business operation must strategize on their marketing and sales to counter the competitive pressure from other business companies. In this light, the implication of Supply Chain Management has been effective in designing companies marketing and sales. Moreover, an integrated supply chain helps companies to position themselves as major products suppliers improving their marketing position within a competitive environment (Kirovska, Josifovska and Kiselicki, 2016, p. 7). Since marketing has become a highly competitive entity; companies that adopt the most significant SCM system especially with the emergence of new players, tend to flourish in their sales and production. A well-developed supply logistic dictates the position of a company in terms of its marketing and sales. SCM helps a company to enhance customer satisfaction through offering quality, reliable, timely service and products. This intern improves the competitive pricing and company performance resulting in a generous profit for the enterprise.

Nevertheless, supply chain management is responsible for integrating different marketing and sales activities such as production, distribution, pricing and advertisement to boost business marketing position. SCM developed marketing evaluation to identify significant targeting regions and customers demand (Luthra, Garg & Haleem, 2013, 930). It also helps in developing a marketing comparison strategy among various factors that influence production, distribution, and consumption in marketing and sales. This helps in sales prediction to avoid risk and loss that a company can possibly incur during operation.

How organization compete with supply chain

Eliminating Redundant Steps in business operations

Companies have adopted strategies in enhancing the efficiency of supply chain management throughout their business operation. One of the processes through which companies manage to establish competition in supply chain management is through eliminating redundant and unproductive steps in the business process (Choi, 2012, n.p). This includes saving salary cost to help workers avoid unnecessary procedures. Additionally, prevent overproduction of commodities and distribution to market in supply management of products helps in eliminating redundant business process. Supply chain management is essential in controlling cost and pricing. Hence, companies must adjust their quality, marketing strategy to ensure standard income profits.

Supply Chain Management assist in the reduction of labor cost and lost sales. Most companies have advanced in their method of production and inventory to ensure less loss is accounted during marketing and stock inventory. Strategies like FIFO and VIVO are some of the inventory tools that are being adopted to enable competitiveness in supply chain management is maintained (Simpson, et al., 2015, 88).

Technology Advancement

Another process that companies have riveted towards competing with the supply chain is through the advancement in technology. Modern innovation in the business organization has created a tremendous impact on how business operates their supply chain management. It is through technology that global marketing and supply chain management has been attained. Companies are able to conduct production distribution, supply, production, and marketing at a global platform. Further, it has increases the target consumers for companies broadening the scale of the supply chain. International organizations operate through the global market to conduct their supply management system (Sharma, 2013, 287).

E-commerce, electronic communication, and internet marketing are all attributes of modernized technology in the supply chain management sector. Companies have advanced the way they supply, distribute and product their product to the consumer without incurring extra costs. Relatively, the incorporation of technology in SCM has widened the scope of business operation for companies further increasing their organization objectives. Technology has simplified how SCM is operated and managed, increasing the use among companies. As a result, the level of competition among companies has increased. Communication tools and planning tool are the chief informational technology advancement that has brought upscale competition in the supply chain management sector.

Value Added Process

Product flexibility, quality, and the general production system also plays a critical part in influencing the process of the supply chain. This influences the competition in cost, distribution, production and supply of commodities to consumers (Kuei, Christian and Chinho, 2010, p. 4458). Additionally, value added process dictate how customer are attracted to products produced by a company. The product flexibility can shift the demand either positively or negatively; same can be accounted for quality and the production system. The value added process is an issue affecting the supply chain management of business (Seth, Goyal & Kiran, 2015, 248). This causes the existence of competition between an organization operation and its supply chain.

Sustainability and Social Responsibility

The external environment is essential in analyzing the factors that ripple competition among business organization and SCM system. The supply chain network is frequently quantified by the social environment or a company. This is determined by the economic, social and environmental issue surrounding the environment. The organization must establish a strong relation with those involved in the logistic networks who are the clients. Aspects of social ethics, culture, and tradition plays a significant role in the supply chain (Ashby, Leat, & Hudson-Smith, 2012, 497). These factors define the business operation and its supply chain management. The external surrounding is responsible for defining the consumer trends and demand in the market; it also influences the distribution, supply and production of the product to the target market. The company must, therefore, comply with their social surrounding and sustainability to effectively conduct supply chain management (Beske & Seuring, 2014, 320).

Social Policies and Regulation

The government also contributes on how organizations compete with their supply chain. Supply chain management laws and regulation are imposed to help control the flow of good and service in any logistic network. This affects the process through which companies operate their supplies, distribution and production of goods. The tax efficiency can influence the globalization of supply chain management among different government operation system. Same applies to international and local policies and regulation in business operations.

Conclusion

Supply chain management has a strategic place in promoting company success and companies must therefore work towards streamlining their supply chains to deliver optimal value. This is particularly important, based on the current trends in the economy that have rendered companies susceptible to unforeseen financial impacts. Effective supply chain management plays the imperative role of boosting customer experience, inventory control, visibility, capital efficiency, marketing and sales competitiveness. In order to sustain this, companies must compete with their supply chain and thus ensure that they provide the best value. This can be done through eliminating redundant business operations, technology advancement, process value addition, promoting sustainability and participating in corporate social responsibility. Adhering to social policy and regulations can enhance a company’s ability to compete with the supply chain.

References

Arlbjørn, J.S., Freytag, P.V. & de Haas, H. 2011, “Service supply chain management”, International Journal of Physical Distribution & Logistics Management, vol. 41, no. 3, pp. 277-295.

Ashby, A., Leat, M., & Hudson-Smith, M. 2012. Making connections: A review of supply chain management and sustainability literature. Supply Chain Management, 17(5), 497-516. doi:http://dx.doi.org/10.1108/13598541211258573

Beske, P. & Seuring, S. 2014, “Putting sustainability into supply chain management”, Supply Chain Management, vol. 19, no. 3, pp. 322. Retrieved form http://search.proquest.com/business/docview/1662703165/6DCAF347FBA34C2EPQ/22?accountid=45049

Chae, B, Olson, D, & Sheu, C 2014, ‘The impact of supply chain analytics on operational performance: a resource-based view’, International Journal Of Production Research, 52, 16, pp. 4695-4710, Business Source Complete, EBSCOhost, viewed 19 April 2016. Retrieved from eds.a.ebscohost.com/ehost/pdfviewer/pdfviewer?vid=7&sid=aaeacbc0-639c-47a8-a0be-b74cdd38d404%40sessionmgr4005&hid=4103

Choi, D. 2012, Supply chain governance mechanisms, green supply chain management, and organizational performance, The University of Nebraska – Lincoln.

Groznik, A., & Trkman, P. (2012). CURRENT ISSUES AND CHALLENGES OF SUPPLY CHAIN MANAGEMENT. Ekonomska Istrazivanja, 25(4), 1101-1112. Retrieved from http://search.proquest.com/docview/1373234468?accountid=45049

Hamister, J.W. 2012, “Supply chain management practices in small retailers”, International Journal of Retail & Distribution Management, vol. 40, no. 6, pp. 427-450. Retrieved from http://search.proquest.com/business/docview/1012564650/6DCAF347FBA34C2EPQ/23?accountid=45049

Kanungo, S 2012, ‘IMPROVED SUPPLY CHAIN MANAGEMENT USING INTEGRATED ERP SYSTEMS’, Global Management Review, 7, 1, pp. 1-4, Business Source Complete, EBSCOhost, viewed 19 April 2016. Retrieved from eds.a.ebscohost.com/ehost/detail/detail?vid=10&sid=aaeacbc0-639c-47a8-a0be-b74cdd38d404%40sessionmgr4005&hid=4103&bdata=JnNpdGU9ZWhvc3QtbGl2ZQ%3d%3d#AN=103541254&db=bth

Kirovska, Z, Josifovska, A, & Kiselicki, M 2016, ‘Efficient Management Of Supply Chain In Achieving A Significant Competitive Advantage In The Market’, Journal Of Sustainable Development (1857-8519), 5, 14, pp. 5-22, Business Source Complete, EBSCOhost, viewed 19 April 2016. Retrieved from eds.a.ebscohost.com/ehost/pdfviewer/pdfviewer?vid=8&sid=aaeacbc0-639c-47a8-a0be-b74cdd38d404%40sessionmgr4005&hid=4103

Kuei, C., Christian N. M., & Chinho L 2011, “Developing global supply chain quality management systems.” International Journal of Production Research 49, no. 15 (August 2011): 4457-4481. Business Source Complete, EBSCOhost (accessed April 19, 2016). Retrieved from eds.a.ebscohost.com/ehost/pdfviewer/pdfviewer?vid=4&sid=aaeacbc0-639c-47a8-a0be-b74cdd38d404%40sessionmgr4005&hid=4103

Lavastre, O, Gunasekaran, A, & Spalanzani, A 2014, ‘Effect of firm characteristics, supplier relationships and techniques used on Supply Chain Risk Management (SCRM): an empirical investigation on French industrial firms’, International Journal Of Production Research, 52, 11, pp. 3381-3403, Business Source Complete, EBSCOhost, viewed 19 April 2016. Retrieved from eds.a.ebscohost.com/ehost/pdfviewer/pdfviewer?sid=aaeacbc0-639c-47a8-a0be-b74cdd38d404%40sessionmgr4005&vid=13&hid=4103

Luthra, S., Garg, D. & Haleem, A. 2013, “Identifying and ranking of strategies to implement green supply chain management in Indian manufacturing industry using Analytical Hierarchy Process”, Journal of Industrial Engineering and Management, vol. 6, no. 4, pp. 930.

Milliken, A.L. 2012, “The Importance of Change Management in Supply Chain”, The Journal of Business Forecasting, vol. 31, no. 2, pp. 4-7,9.

Richey, R. G., Hilton, C. B., Harvey, M. G., Beitelspacher, L. S., Tokman, M., & Moeller, M. (2011). Aligning operant resources for global performance: An assessment of supply chain human resource management. Journal of Management and Organization, 17(3), 364-382. Retrieved from http://search.proquest.com/docview/871907441?accountid=45049

Sandberg, E., & Abrahamsson, M. (2010). The role of top management in supply chain management practices. International Journal of Retail & Distribution Management, 38(1), 57-69. doi:http://dx.doi.org/10.1108/09590551011016331

Seth, M., Goyal, D.P. & Kiran, R. 2015, “Development of a Model for Successful Implementation of Supply Chain Management Information System in Indian Automotive Industry”, Vision, vol. 19, no. 3, pp. 248-262. Retrieved from http://search.proquest.com/business/docview/1721486842/6DCAF347FBA34C2EPQ/26?accountid=45049

Seuring, S. & Gold, S. 2012, “Conducting content-analysis based literature reviews in supply chain management”, Supply Chain Management, vol. 17, no. 5, pp. 544-555.retrived from

Sharma, M.M. 2013, “A Study on the Concept of Green Supply Chain Management”, Journal of Supply Chain Management Systems, vol. 2, no. 1, pp. 1-7 Gould, J.E., Macharis, C. & Haasis, H. 2010, “Emergence of security in supply chain management literature”, Journal of Transportation Security, vol. 3, no. 4, pp. 287-302.retrived from http://search.proquest.com/business/docview/807496072/6DCAF347FBA34C2EPQ/11?accountid=45049

Simpson, D., Meredith, J., Boyer, K., Dilts, D., Ellram, L.M. & Leong, G.K. 2015, “PROFESSIONAL, RESEARCH, AND PUBLISHING TRENDS IN OPERATIONS AND SUPPLY CHAIN MANAGEMENT”, Journal of Supply Chain Management, vol. 51, no. 3, pp. 87-100.reftrieved from http://search.proquest.com/business/docview/1695970875/6DCAF347FBA34C2EPQ/30?accountid=45049

We can write this or a similar paper for you! Simply fill the order form!